Tubular Centrifuge

We are Manufacturer, Supplier, Exporter of Tubular Centrifuge from Mumbai, Maharashtra, India.

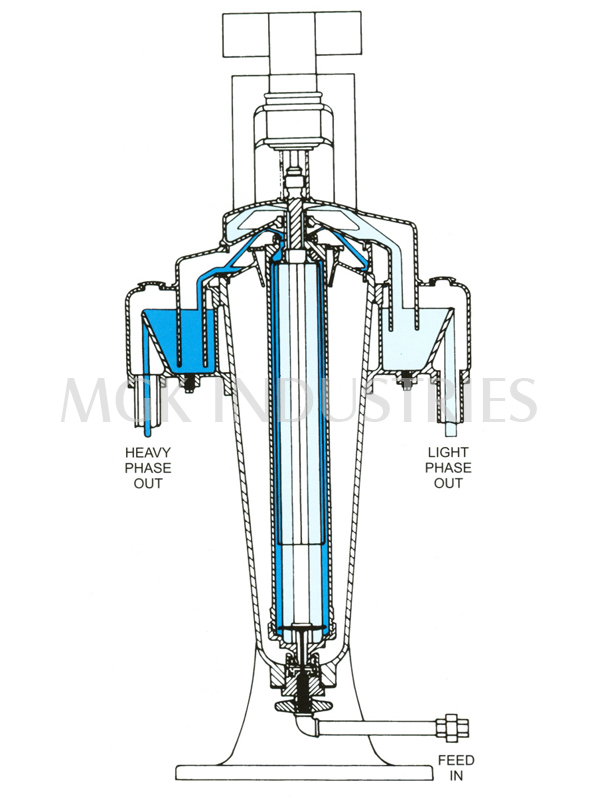

HOW THE SUPER-CENTRIFUGE OPERATES

This sectional view of a super-Centrifuge shows the application of centrifugal force to separate a mixture of two immiscible liquids that may contain fine suspended solids, in small quantities, heavier than either liquid.

The mixture enters the Super-Centrifuge through an inlet at the base of the machine, and is introduced into the hollow cylindrical rotor which has two sets of openings at the top to allow discharge of the separated liquids. The rotor turns at 15,000 r.p.m. oг higher, and generates a centrifugal force in excess of 13,000 times the force of gravity.This force separates the two liquids according to their specific gravities into concentric cylindrical layers. The lighter liquid is nearer the centre of the rotor and the heavier liquid forms the outside layer. At the same time th solids are deposited against the rotor wall.

The operation of the Super-Centrifuge is continuous, with the separated liquids being continuously displaced upwards by the incoming mixture, and discharged through their respective outlet ports at the top of the rotor. The layer of accumulated solids that builds up on the rotor wall is cleaned out when the centrifuge is shut down.

The flow from the covers is generally by gravity. A rotor designed to separate two liquids continuously, is known as a "separator".

For removal of fine solids from a liquid a "clarifier" bowl is provided, for polishing the liquid.

| MECHANICAL SPECIFICATIONS | ||||

| MODEL | AS12 / HC | AS16 | AS18 | AS26 |

| BOWL SPEED (MAXIMUM) | 15000 | 17000 | 15000 | 17000 |

| MAXIMUM CENTRIFUGAL FORCE | 13200 | 17000 | 13200 | 20000 |

| TOTAL BOWL CAPACITY | 3.1 litres | 6 litres | 6 litres | 9 litres |

| BOWL DIRT CAPACITY | 2 litres | 3.5 litres | 3.5 litres | 5.25 litres |

| BOWL WEIGHT | 11 kg. | 17 kg. | 17 kg. | 25 kg. |

MINERAL OIL PURIFIERS |

||||||

| CAPACITY LITRES / HR | ||||||

MODEL |

CRUDE OIL |

MACHINE OIL |

HYDRAU- LIC OIL |

LUBE OIL |

DIESEL OIL |

HEAVY FUEL OIL |

AS12 |

550 |

250 / 550 |

700 |

700 |

700 |

- |

AS12HC |

800 |

400 / 800 |

1000 |

1000 |

1000 |

- |

AS16 |

1800 |

1500 / 1800 |

1800 |

1800 |

1800 |

- |

AS26 |

3500 / 4500 |

3000 / 4000 |

4000 / 4500 |

4000 / 4500 |

4000 / 4500 |

- |

Tubular Centrifuges are high-speed separation devices used for the continuous separation of immiscible liquids or the clarification of liquids containing fine suspended solids. These centrifuges are designed to handle small to medium batch sizes and are widely utilized in various industries for their efficiency and reliability in separating complex mixtures. The core of a Tubular Centrifuge is a high-speed rotating bowl, which creates a strong centrifugal force to separate substances based on their densities.

The design of Tubular Centrifuges typically includes a tubular bowl made from high-quality materials such as SS (Stainless Steel) to ensure durability and resistance to corrosion. The centrifugal force generated by the high-speed rotation of the bowl causes the denser components to move outward to the bowl wall, while the lighter components remain closer to the center. This efficient separation process results in high-purity outputs, making Tubular Centrifuges essential for applications requiring precise separation and clarification.

Tubular Centrifuges are equipped with advanced features to optimize performance and ensure user safety. They are designed to operate at high speeds, achieving rapid separation and processing rates. The compact design of these centrifuges allows for easy integration into existing production lines, and their robust construction ensures long-term reliability. Additionally, Tubular Centrifuges are designed for easy maintenance, with accessible components and straightforward cleaning procedures.

Tubular Centrifuges provide an effective and reliable solution for a wide range of industrial separation and clarification needs, ensuring high-quality outputs and efficient processing.

Salient Features

- High-speed rotation for efficient separation and clarification

- Durable construction using high-quality materials such as SS (Stainless Steel)

- Compact design for easy integration into existing production lines

- Advanced safety features to ensure reliable and safe operation

- High-purity output due to precise separation capabilities

- Low maintenance requirements with accessible components

- Suitable for continuous operation, enhancing productivity

- Adjustable parameters to accommodate different separation requirements

Applications

- Pharmaceutical industry for the separation of active ingredients and impurities

- Chemical processing for the clarification of solutions and separation of phases

- Food and beverage industry for the purification of liquids and removal of fine solids

- Biotechnology for the separation of cellular components and purification of biological products

- Oil and gas industry for the clarification of lubricants and separation of water-oil mixtures

- Environmental engineering for the treatment of wastewater and recovery of valuable substances

- Dairy industry for the separation of cream from milk and clarification of whey

- Cosmetics industry for the production of emulsions and removal of impurities